The pressure vacuum relief valves are specialized equipment used in processes where gas and/or venting vapors must be piped away. The discharge of the gases on the pipeline reduces the environmental impact that gases have when they are release directly to the atmosphere and increases the protection and safety against fire in the storage tanks.

Specifications:

| Sizes: | 2” to 12”. |

| Materials: | Aluminum, Carbon Steel, Stainless Steel, Fiber Glass and other materials. |

| Pressure: | 0.5 osig to 15 psig. |

| Vacuum: | 0.5 osig to 12 psig. |

| Certifications: | ATEX and PED approval. |

| Connections: | 150#ANSI, PN10, PN16 and JIS. |

| Diaphragm: | Buna-N, Fluoropolymer, FKM and others. |

Online Support

The gas storage systems are technologies that allow to store gas and/or venting vapors in a constant pressure. The gas storage equipment has two membranes, the outer that provides environmental conditions protection and the inner that contains the gas, which are installed on a concrete base or upon the storage tanks.

The gas storage systems are technologies that allow to store gas and/or venting vapors in a constant pressure. The gas storage equipment has two membranes, the outer that provides environmental conditions protection and the inner that contains the gas, which are installed on a concrete base or upon the storage tanks.

Specifications:

Online Support

The Vapor Recovery Units (VRU) are one of the most efficient equipment to capture the gases and/or venting vapors from storage tanks, through a compression or an adsorption process. The adsorption process is compounded of three stages: Vapors adsorption with activated carbon, activated carbon regeneration and vapors re-adsorption with an absorbent liquid.

Specifications:

Online Support

Gas Temperature Conditioning is an integrated system between ammonia chillers and tubular heat exchangers.

The tubular heat exchangers are an optimum solution to provide a thermal treatment to the gases and/or to the venting vapors. The purpose of this treatment is to reduce gas temperature in order to condensate liquids and increase quality of gases and/or vapors.

Specifications:

| Cooling temperature: | Up to -30°C |

| Design Pressure: | 10 barg. |

| Length: | 1m to 6m. |

| Case: | 60.3 mm to 1500mm. |

| Inner Tubes: | From 10mm. |

| Materials: | Stainless Steel and other materials. |

| Options: | -Glass wool isolation. -Versatility to install for serial equipment. |

Online Support

The treatment gas plants are systems developed to remove Sulfur (H2S), Carbon Dioxide (CO2) and others gas pollutants, to increase gas quality in RUT (Reglamento Único de Transporte de Gas Natural) conditions and/or improve the methane concentration.

Specifications:

Online Support

Technology to remove pollutants gases (H2S, CO2, H2O and others), through a separation process using selective membranes. This is useful to recovery condensates liquids.

Technology to remove pollutants gases (H2S, CO2, H2O and others), through a separation process using selective membranes. This is useful to recovery condensates liquids.

Specifications:

Online Support

The power generation units are designed to reduce Volatile Organic Compounds (VOC) emissions and at the same time reduce consumption of electricity trough power generation, using a custom designed gas engine with a system of dual fuel injection.

The power generation units are designed to reduce Volatile Organic Compounds (VOC) emissions and at the same time reduce consumption of electricity trough power generation, using a custom designed gas engine with a system of dual fuel injection.

Specifications:

Online Support

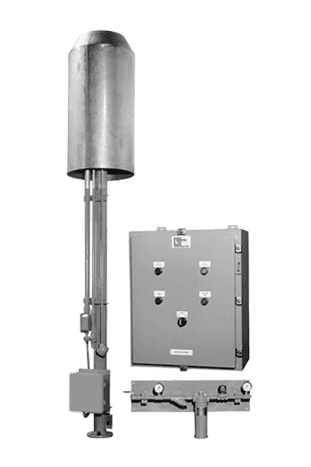

The gas flares are equipment designed to high efficiency combustion of storage tanks gases and/or venting vapors, through a controlled, safety and efficient process that reduce the environmental impact of gases released into the atmosphere.

The gas flares are equipment designed to high efficiency combustion of storage tanks gases and/or venting vapors, through a controlled, safety and efficient process that reduce the environmental impact of gases released into the atmosphere.

Specifications:

| Sizes: | 2” to 75”. |

| Materials: | Stainless steel in the flare zone. |

| Supply pressure: | 4 InWC to 10 psig. |

| Flow: | 22 SCFH to 150 SCFH. |

| Options: | NEMA 4(X) and NEMA 7. |

Online Support